Crescent Gage & Tool

Sales & Services

Measurement Services, Gaging Equipment Sales, Calibration Services, Metrology Training and Support.

Since 1971

Quality & Commitment

Since 1971, Crescent Gage has been in business selling, supporting and servicing dimensional inspection and measuring equipment. Quality is the most important entity in our business.

Our commitment is to satisfy our customers, the companies we represent, and our co-workers, by providing error-free products and services that exceed their expectations every time.

We Solve Problems

Whatever your metrology challenge, our team of seasoned professionals have the skills and knowledge to help you solve it. Our goal is to understand your needs and provide the best solution/equipment for the job, every time!

Process

Our team will guide you every step of the way from selecting the right measurement solution, to successful implementation.

Partnerships

We believe the best way to help you win is to build a long term relationship. We serve you as trusted consultants, experienced trainers for your team, and knowledgeable technicians to support your measurement needs.

Championing

When you win, we win. Our goal is to help your technicians who use CMMs and other Metrology tools be a champion! Our team is highly responsive and available to assist your team in the field, and help them meet their job requirements.

Complete and Accurate Data

We understand that selecting the right measurement solution ensures that production deadlines are met, your parts are manufactured correctly and your company is profitable.

Products & Solutions

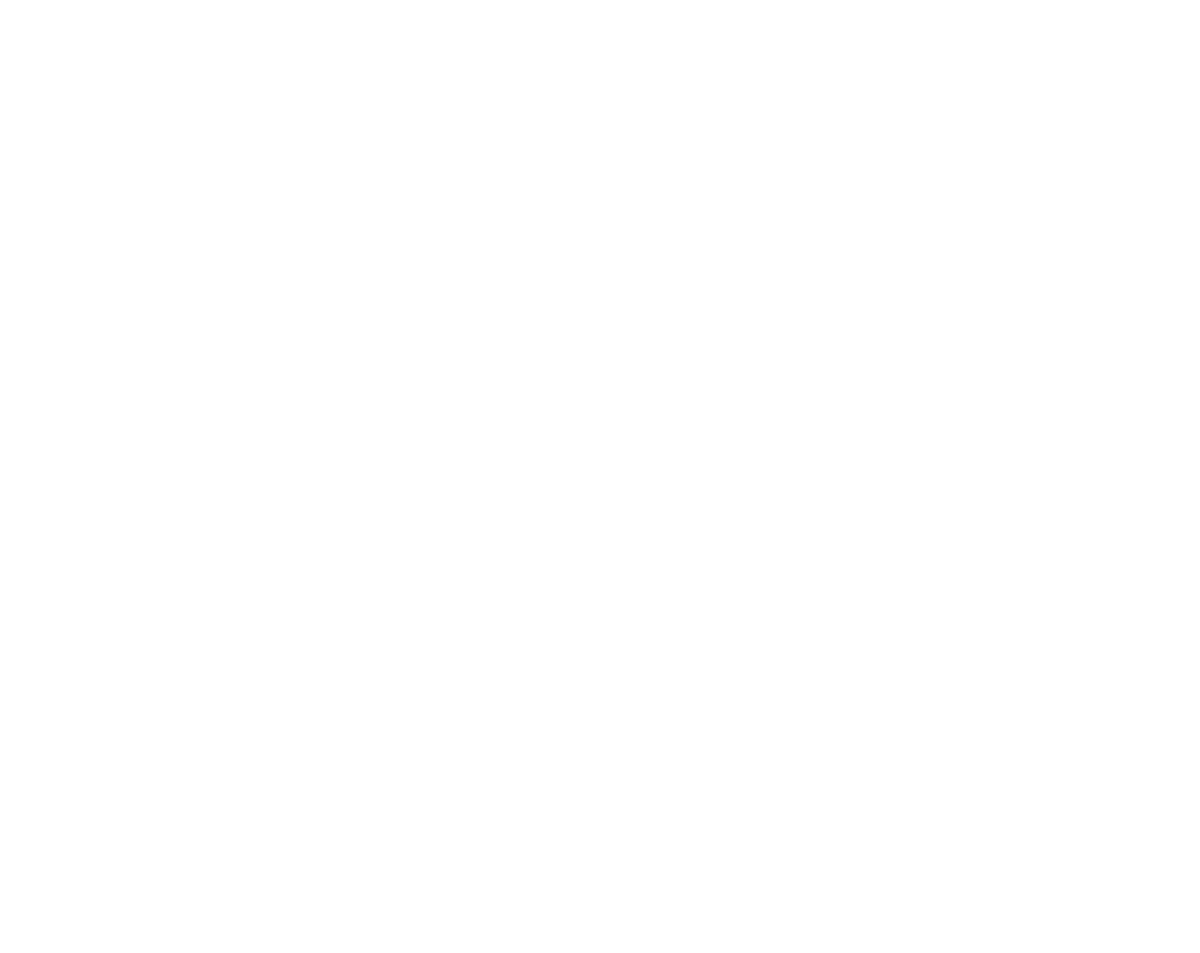

Measurement Services

Combining decades of experience with the latest technology, we help you achieve your measurement goals by providing complete and accurate comparison data of your parts per your specified requirements.

Our services include First Article Inspections (FAI), in-process validation, source inspections, capability studies, surface finish, 3D scanning, and more.

Precision

Metrology is a precision industry. We take pride in performing measurements with the highest level of detail & quality to ensure your parts are the exact size they are required to be.

Tolerances

By using the latest technology, we have the advantage of measuring to extremely tight tolerances. This includes mission critical industries & applications.

Reverse Engineering

Have a CAD & no drawing? Have a drawing & no CAD? Have a part and no drawing or CAD model? We can help by reverse engineering your part to the exact specs needed.

Error Free measurements

We help you reduce scrap & mitigate risk by providing you with accurate, error free measurements that meet even the most discriminating standards.

Training & Support

Our team of knowledgable experts provide turnkey support for all your measuring equipment, software, and operations. From setup and training of your team, to onsite maintenance support, we help you maximize your investment and attain your production goals.

Training

- Hardware and Software training

- Factory certified CMM & Vision System classes

- GD&T Consulting (including compliance & best practices)

On-site Support

- Quick response

- Calibrations

- Customized training

- Program/inspection runtime optimization

- Programming & implementation

- Equipment & process validation

Industries We Serve

We help clients across a variety of industries solve their measuring challenges, and apply the latest technology to match the right metrology measurement solution for the job. Here are a few of the industries that trust us with their mission critical projects.

Medical Devices

From orthopedic devices, to surgical robotics, we identify design and manufacturing issues to ensure consistency and accuracy in devices that impact the everyday life of patients.

Plastic Injection Molding

Manufacturers rely on our team to verify molds thoroughly, troubleshoot production issues, and get parts through first article inspections (FAI) quickly and accurately .

Aerospace

Engineers and mechanics trust us to measure extremely tight tolerances that minimize engine vibration and increase bearing life, ensuring in-flight safety.

SemiConductor & Electronics

Chip and Integrated Circuit (IC) manufacturers rely on extremely tight measurement tolerances to ensure performance and integrity of IC film, IC wafers and related components.

Oil, Gas, & Energy

The Oil, Gas, and Energy industry relies on our services to help reduce costly errors, minimize safety concerns, and increase production efficiency.

Military & Defense

Our extensive knowledge and state-of-the-art equipment allows us to inspect precise components and highly sensitive projects that contribute to mission critical operations within the military and defense sectors.

Common Project Types

Manufacturers depend on our dimensional inspection services for a wide variety of projects. Here are a few of the common solutions we assist with.

3D Printing

Additive Manufacturing

Wire EDM

Robot Cell Integration & Automation

NPS Scores

Net Promoter Score

Communication Prior To Service

Technician Timeliness

Meeting Customer Service Expectations

Technician's Overall Rating

What our Clients say about us

Crescent Gage is always my first choice for inspection services and support. Richard and Dennis provide exceptional service and always provide reasonable, fair, and competitive pricing.