The powerhouse of resolution for CT inspection and metrology

ZEISS METROTOM 6 scout (GOM CT)

ZEISS METROTOM 6 scout (GOM CT) digitizes complex parts including the internal geometries at the finest level of detail. You get a complete 3D image for GD&T analyses or nominal-actual comparisons. The metrology CT particularly excels in digitizing small plastic parts.

How you benefit:

- Extremely high resolution

thanks to a 3k X-ray detector (3008 x 2512 pixels) - High precision

due to mathematical modeling of the measuring room - Automatic object positioning

via 5-axis kinematics and live view in the software - All-in-one software

for a consistent, fast workflow

Resolution

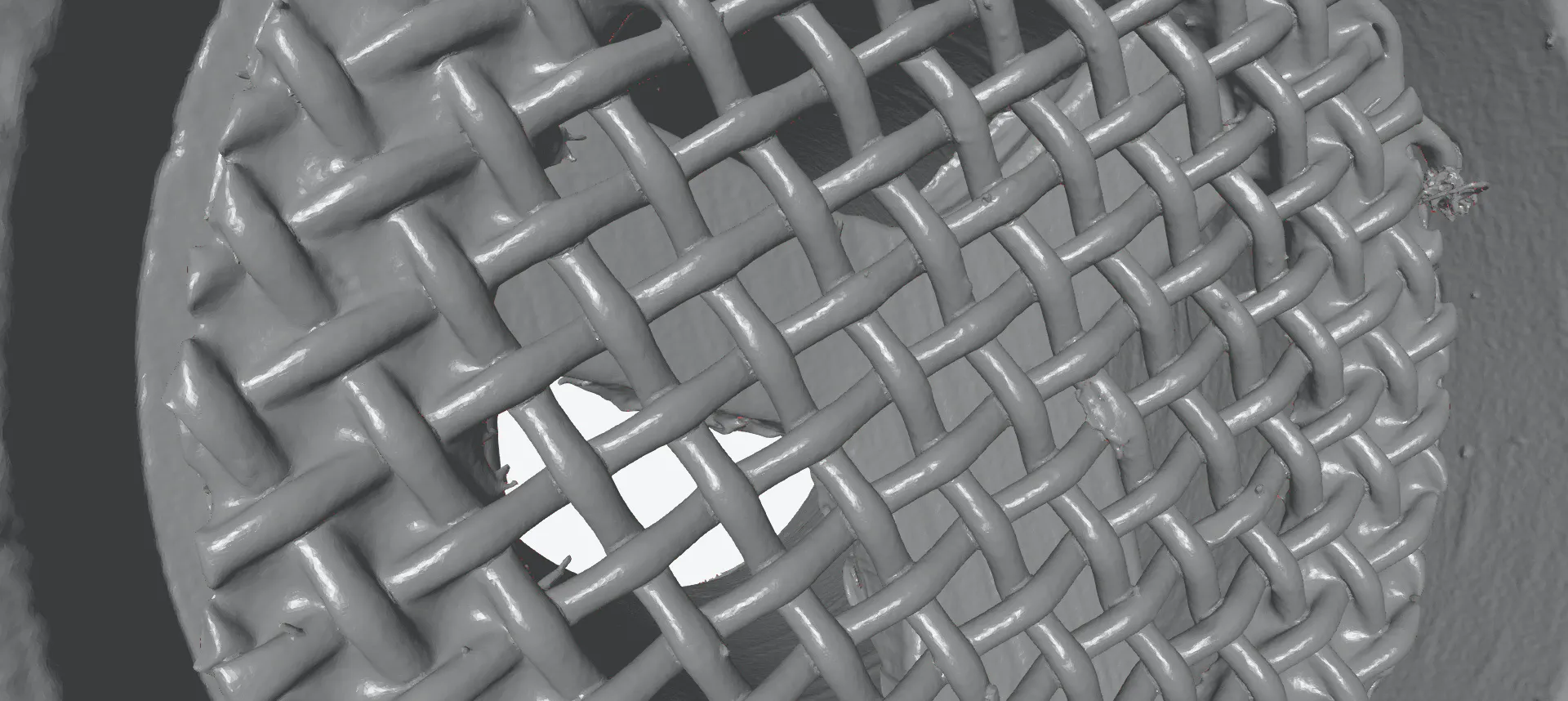

When digitizing a part, ZEISS METROTOM 6 scout (GOM CT) achieves an outstanding sharpness of detail: On the one hand, because it uses a high-resolution 3k X-ray detector for acquiring measuring data and on the other hand, because each part is measured in the best possible measurement position and thus always in the highest possible resolution. You can see the result below: on the left, measuring data generated with ZEISS METROTOM 6 scout (GOM CT) and on the right the usual standard.

For producing its precise 3D measuring data, ZEISS METROTOM 6 scout (GOM CT) applies mathematical intelligence: It combines perfectly interconnected algorithms throughout the measuring sequence with digital modeling of the measuring room. Additionally, the system features optimized mechanical stability of all components that are relevant for performing the measurement. The bottom line: Based on the measuring results, you can evaluate a part’s quality in a truly reliable, highly precise way and conduct further analysis.

Easy centering of the part

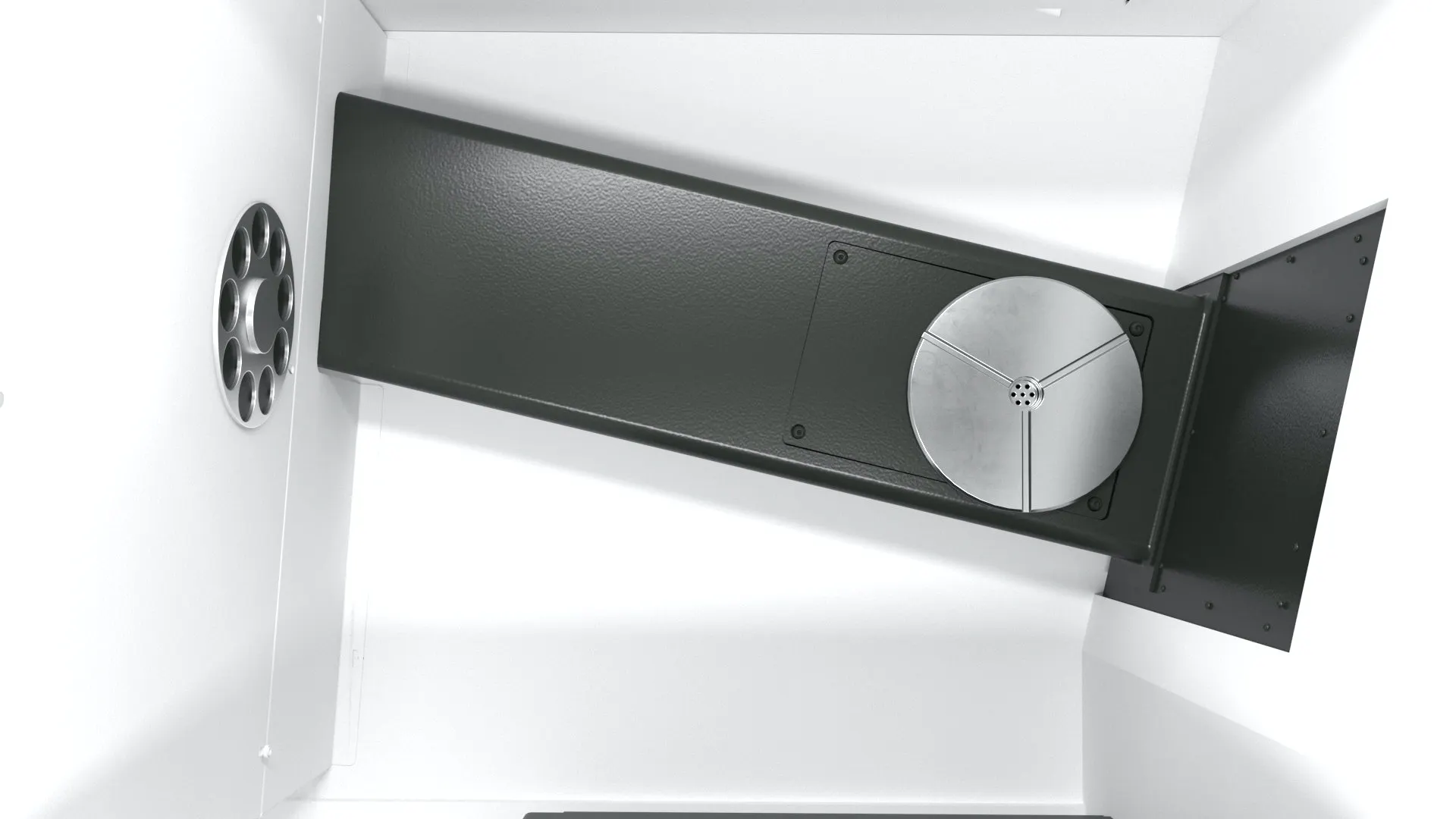

Automatic object positioning

A 5-axis kinematics with integrated centering table helps you to optimally position the part in the measuring volume. You simply place it in the machine’s measuring room – the rest is done by the software.

All-in-one software

The control of the device and the metrological evaluation of the data are combined in a single software package, making additional software or intermediate steps redundant. The process chain from the recording of the raw data through the inspection up to the creation of a measuring report is significantly simplified.

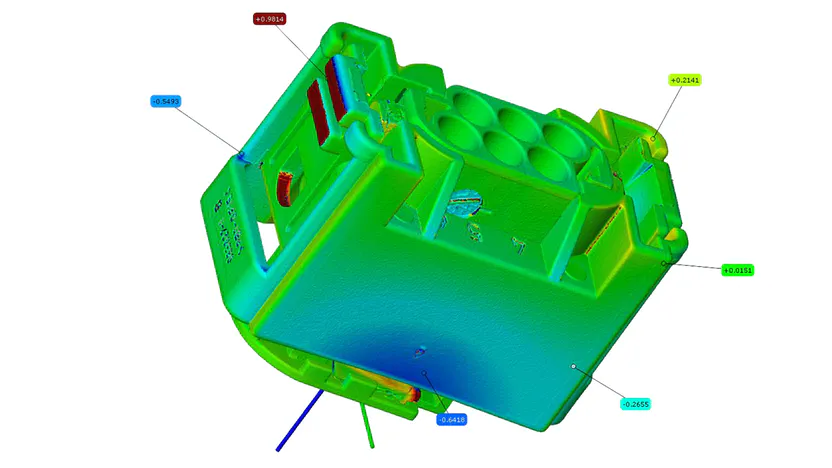

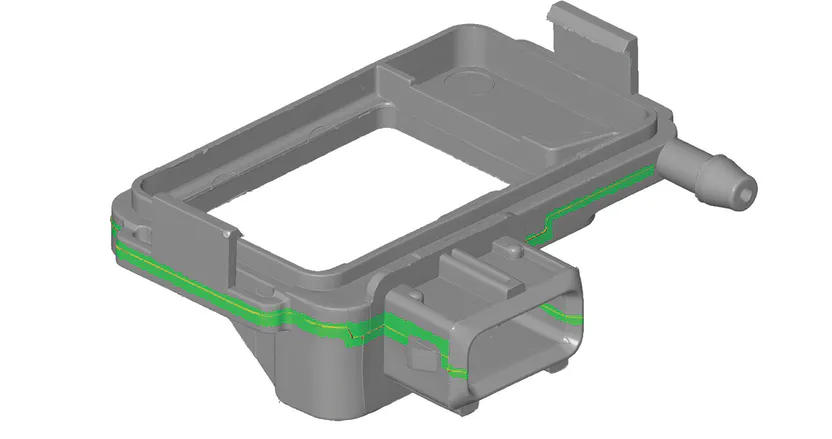

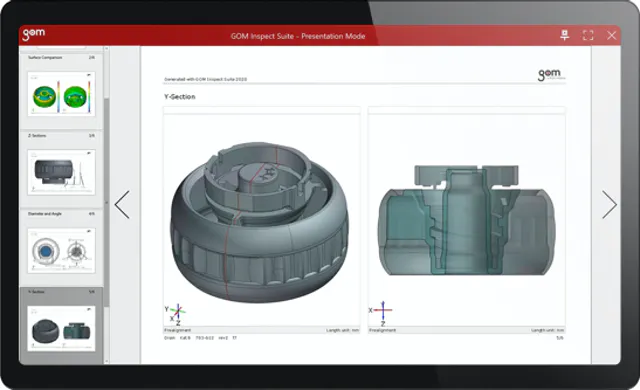

Comprehensive evaluation with GOM Volume Inspect

GOM Volume Inspect allows complete CT data analysis in 3D to evaluate the part quality and optimize your manufacturing process. Individual sectional images allow you to view the volume layer by layer, making even the smallest details and defects visible. The detected defects can be analyzed in detail and automatically evaluated according to various criteria. In addition, you can load volume data of several components into a project, perform a trend analysis and compare the analysis with CAD data. All measurement results are documented and finally combined in a well-structured report. Intuitive operation and high performance: CT data analysis has never been easier!

One CT system, several advantages

ZEISS METROTOM 1 is the ideal device to upgrade your quality inspection portfolio using industrial computed tomography. The CT system boasts with many advantages:

Easy handling

ZEISS METROTOM 1 is built with the user in mind. Installation is a simple process and only little training is needed for being able to use the CT. It just takes one click to start a scanning process!

Precise measurements

Small but thorough: With ZEISS Metrotom 1 you can measure and evaluate complete parts. This allows you to perform accurate nominal/actual comparisons, dimensional checks, and wall thickness analyses with the confidence that you can rely on your measurements.

Small footprint

ZEISS Metrotom 1 is surprisingly compact. Its dimensions are 1750 mm (W) x 1820 mm (H) x 870 mm (D). That means the CT system fits into any metrology lab - allowing you to carry out in-house measurements and quality assurance without external measuring services.

Fast return on invest

In addition to low acquisition costs, the cost of ownership is also kept to a minimum thanks to the low-maintenance system: The tube of ZEISS METROTOM 1 does not need to be maintained when in operation.

ZEISS METROTOM 1 - reliable and compact

Progressive CT technology for every metrology lab

ZEISS is an expert in the field of CT technology and has been providing reliable CT systems as part of the METROTOM family for over a decade. The computed tomography system ZEISS METROTOM 1 now makes reliable X-ray technology and non-destructive quality assurance available to everyone.

Measure entire components. Guarantee flawless parts.

With ZEISS METROTOM 1, hidden defects of workpieces can be detected with ease in your measuring lab. Whether medium or small sized parts, plastic or light metal - with ZEISS METROTOM 1, you can inspect a variety of parts such as connectors, plastic caps, aluminum parts and more.

GOM Volume Inspect

Comprehensive CT data analysis in 3D

ZEISS METROTOM 1 comes with the operation and inspection software GOM Volume Inspect. The software is suitable for beginners and combines all stages of the CT process from scan set-up and reconstruction to data evaluation and reporting. Geometries, shrinkage holes or internal structures and assembly situations can be evaluated precisely. Even the smallest defects become visible thanks to individual sectional images and can be automatically evaluated using a wide range of criteria. With just one software, you can load volume data from several components into a project, perform a trend analysis, compare the captured 3D data with the CAD model and more.

Experience how the system works

Technical data

Features

| X-Ray source | 225 kV |

| X-Ray detector | Resolution: 3008 x 2512 pixels |

| Measuring area | d:240 mm h: 400 mm |

| Voxel size | 2 µm – 80 µm |

| Dimension | H. 2210 mm W. 2200 mm D. 1230 mm |

| Weight | 4800 kg |

| Fields of application | first article inspection, tool correction, inspection during ongoing production |

| Inspection features | internal structures, wall thickness, material defects, pores and shrinkage cavities |

| Measuring tasks | GD&T analysis, nominal-actual comparison, assembly analysis |

Available services:

ZEISS Academy Metrology

Qualification tools and services, customized to your needs and ready to elevate your skills and expertise.