Surfcom

Intuitively Operated Surface Texture Measuring Instruments

SURFCOM TOUCH Series

Surface roughness solution for any measurement challenge

Our intuitively operated surface texture measuring instruments allow easy roughness measurements of various types of workpieces.

SURFCOM TOUCH Series

Features

All SURFCOM TOUCH systems come with an intuitive and easy-to-use screen for condition setting,

calibration, measurement and analysis. An amplifier with a 7-inch wide touch panel and a new interface provides higher operability. Easy-to-use operation eliminates the need of instructions.

Advantages

- Settings can be performed such as language, icon layout, management of internal memories and USB memories.

- Multi-language support available worldwide

- Easy-to-follow user’s guide/quick reference guide

- USB/micro USB ports as standard equipment

- Measurement results can be printed quickly

SURFCOM TOUCH 35/40/45

Portable surface roughness solution for any measurement challenge

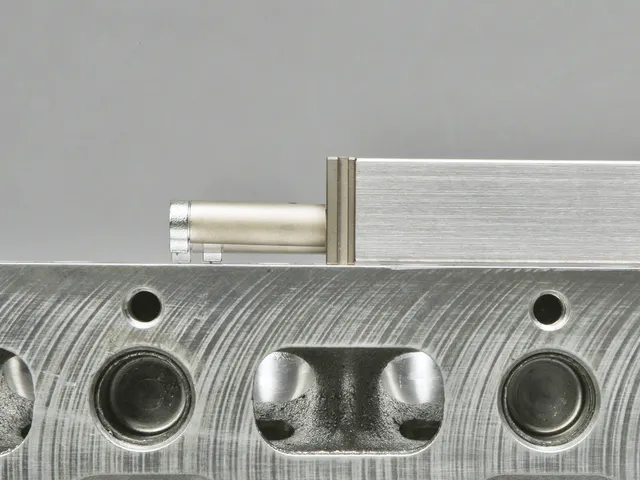

The system is available with three small and light weight skidded tracing drivers for measurement with different attitudes. In addition to horizontal surfaces, measurement on vertical surfaces can be performed in narrow areas with a transverse trace.

Advantages of the portable surface roughness solutions

- Palm-sized tracing drivers selectable for workpieces and measurement areas

- A calibration table offered as an accessory makes calibration work easy

- Optional pickups allow for various types of measurement

SURFCOM TOUCH 50

Surface roughness and straightness in one compact machine

Extended Z-axis measurement range

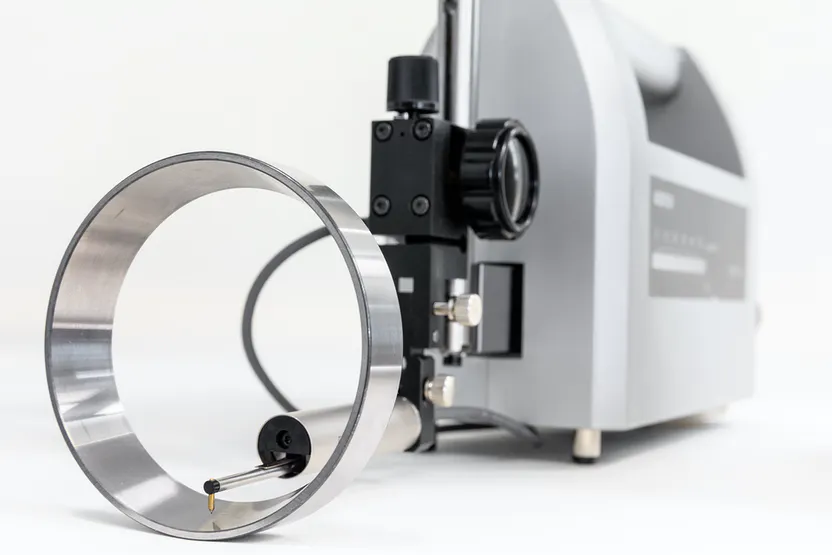

The high performance pickup with an extended measurement range from 800 to 1,000 μm and a Z-axis minimum resolution of 0.0001 μm allows for wide-range and high resolution skidless measurement. In addition to a flat surface, the roughness or waviness on an undulating surface such as a stepped or round surface can be evaluated with one trace.

Full flexibility

Skidless measurement with a high performance pickup while having high resolution and with a wide measuring range. Various types of workpieces can be measured by changing the stylus for deep, long, or small holes or a round surface.

Advantages of SURFCOM TOUCH 50

- Suited for measuring cylindrical workpieces, a tracing driver can be placed on work piecies by using an optional roll footing.

- SURFCOM TOUCH 50 can be connected with a handytype tracing driver.

SURFCOM TOUCH 550

High-end solution with an electric column offering high accuracy and size variation

Extended measuring range

The high performing pickup with an extended measurement range from 800 to 1,000 μm and a Z-axis minimum resolution of 0.0001 μm allows for wide-range and high resolution skidless measurement. No need to consider measurement range. In addition to flat surface, the roughness or waviness on undulating surface such as stepped or round surface can be evaluated with one trace. Leveling and zeroing before measurement can also be performed easily.

Flexibility in terms of machine size

SURFCOM TOUCH 550 allows users to select a combination of the size of the granite base, the height and type of the column and the drive range in the X-axis direction.

Optional Equipment

An optional compact measurement stand for measuring high workpieces or measuring with jigs.

ZEISS SF&G SURFCOM Technical Data

SURFCOM TOUCH 35/40/45

| SURFCOM TOUCH 35 | SURFCOM TOUCH 40 | SURFCOM TOUCH 45 | |

| Z direction | -210 to +160 μm | -210 to +160 μm | -210 to +160 μm |

| Drive axis | X direction 16 mm | X direction 16 mm | Y direction 4 mm |

| Movement type | Standard type | Retraction type | Horizontal tracing type |

| Evaluation length | 0.2 to 16 mm | 0.2 to 16 mm | 0.2 to 4.0 mm |

| Measurement speed | 0.5, 0.6, 0.75, 1.0 mm/s | 0.5, 0.6, 0.75, 1.0 mm/s | 0.6 mm/s |

SURFCOM TOUCH 50

| SURFCOM TOUCH 50 | |

| Z direction | ±500 μm |

| X direction | 50 mm |

| Evaluation length | 0.1 to 50 mm |

| Straightness accuracy | 0.3 μm/50 mm |

| Detector vertical movement volume | 50 mm |

| Measurement speed | 0.15, 0.3, 0.6, 1.5, 3 / 0.05, 0.1, 0.2, 0.5, 1 mm/s |

SURFCOM TOUCH 550

| SURFCOM TOUCH 550 | |

| Z direction | ±500 μm |

| X direction | 100 mm to 200 mm |

| Drive distance | 100 mm to 200 mm |

| Straightness accuracy | (0.05 + 1.5L/1000) μm |

| Measurement speed | 0.03, 0.06, 0.15, 0.3, 0.6, 1.5, 3, 6 / 0.05, 0.1, 0.2, 0.5, 1, 2, 5 mm/s |

L: measurement length (mm)