ZEISS SF&G Touch

Compact Form Tester for Production

RONDCOM TOUCH

Accurate and effective with simple TOUCH operation

Direct and uncomplicated measurement during the manufacturing process – thanks to its easy operation this is no problem for RONDCOM TOUCH.

RONDCOM TOUCH

Features

RONDCOM TOUCH is ideal for self-tests directly in production. Thanks to its compact design, the form tester is suitable for any workbench.

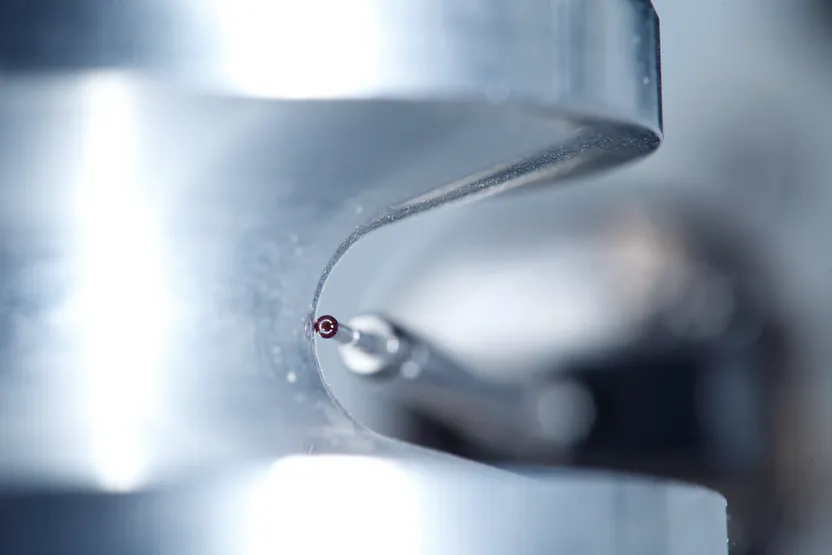

Excellent rigidity

The form tester features a movable X axis, allowing it to reach workpieces from all sides without difficulty. Another key benefit is the rotary table on air bearings that achieves extremely high rotational accuracy thanks to its excellent rigidity. In addition, the non-contact travel ensures measurement results that are totally uninfluenced by drive vibrations.

Small and smart

RONDCOM TOUCH also captures very narrow tolerances and the blue tooth function of the form tester allows simple and wireless printing of the measurement results. The compact design makes the standard R axis unnecessary.

Detailed measuring reports

The software ACCTee PRO provides support in the semiautomatic alignment of the part. Just three touches of the touch screen suffice to receive a detailed measuring report. Alternatively, RONDCOM TOUCH can also be operated via a conventional desktop PC.

All advantages at a glance

- Compact design – perfect for any workbench

- Movable X axis

- Faster thanks to patented semi-automatic alignment

- Simple touchscreen operation (optional)

- Wireless operation and printing via blue tooth or USB cable

- Ideal for measuring precision workpieces up to 15 kg

Flexibility in terms of machine size

SURFCOM TOUCH 550 allows users to select a combination of the size of the granite base, the height and type of the column and the drive range in the X-axis direction.

Optional Equipment

An optional compact measurement stand for measuring high workpieces or measuring with jigs.

Technical Data for RONDCOM TOUCH

|

max Ø / Z / weight |

RONt |

Resolution for form |

|

150/160/15kg |

0.04+(6H/10000) |

max. 0.002µm |