ZEISS MMZ-G

Unparalleled Greatness

ZEISS MMZ G

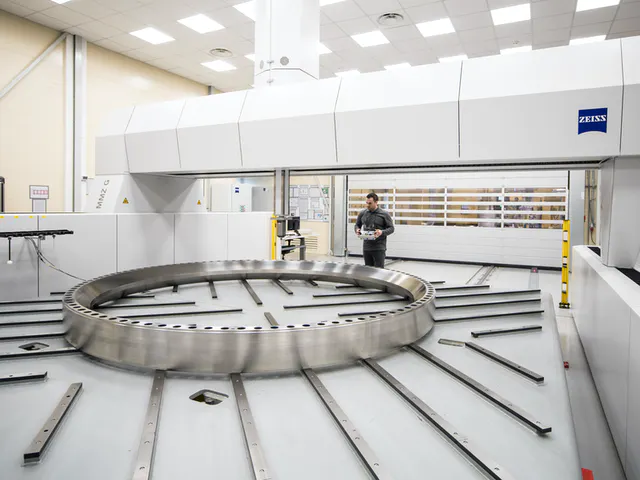

Bridge-type CMM for large workpieces

Large bridge-type machines in the ZEISS MMZ G line meet the highest demands: they feature the largest measuring range of all measuring machines offered by ZEISS and offer you unparalleled accuracy. This makes the ZEISS MMZ G ideal for checking complex, extremely large workpieces, especially those with tight tolerances.

ZEISS MMZ G

Features

ZEISS MMZ G measuring machines are used by manufacturers of printing machines, wind turbines, and in mechanical engineering.

Minimized subsequent costs

- Durable thanks to the robust roller bearings

- Minimal expenses for worn parts because of transverse force-free drives

- Extremely sturdy because of its very stable mechanical design

Ergonomically-correct work

- All-sided view of the measuring range

- Walk-in measuring area for effective analysis directly on the work piece

- Mobile data station for direct programming on the work piece

Exceptional scanning performance

- ZEISS VAST navigator to quickly calibrate, scan and increase precision

- ZEISS VAST performance to increase measuring throughput

- REACH CFX 3 MMZ stylus extensions for measuring deep boreholes (1,200 mm)

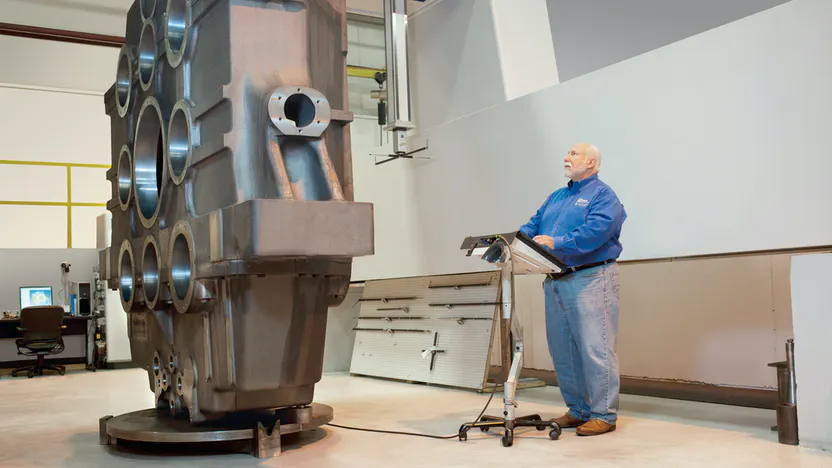

Measure extremely heavy workpieces dependably

- Resistant to harsh environmental conditions for minimal demands on the measuring room

- Large bearing clearances and a stable bridge design for an exceptional scanning performance

- Workpiece weight limited only by the thickness of the foundation

Three-M Tool and the ZEISS MMZ G

large coordinate measuring machine

"Having the ZEISS CMM made it possible to edge out the competition and keep our big vision alive

- Michael Medwid, President at Three-M

Technical Data for ZEISS MMZ G

| Length measurement error | MPE_E150 | from 2.2 + L/400 μm |

| Single stylus probing error | MPE_PFTU | from 2.0 μ |

| Scanning probing error | MPE_THP/tau | from 2.8 μ / 62 s |

| Form measuring error | MPE RONt | from 2.0 μm |

Available software:

ZEISS CALYPSO

The easy way to get from the drawing to the measurement

ZEISS GEAR PRO

Gear metrology