T-Scan

ZEISS T-SCAN

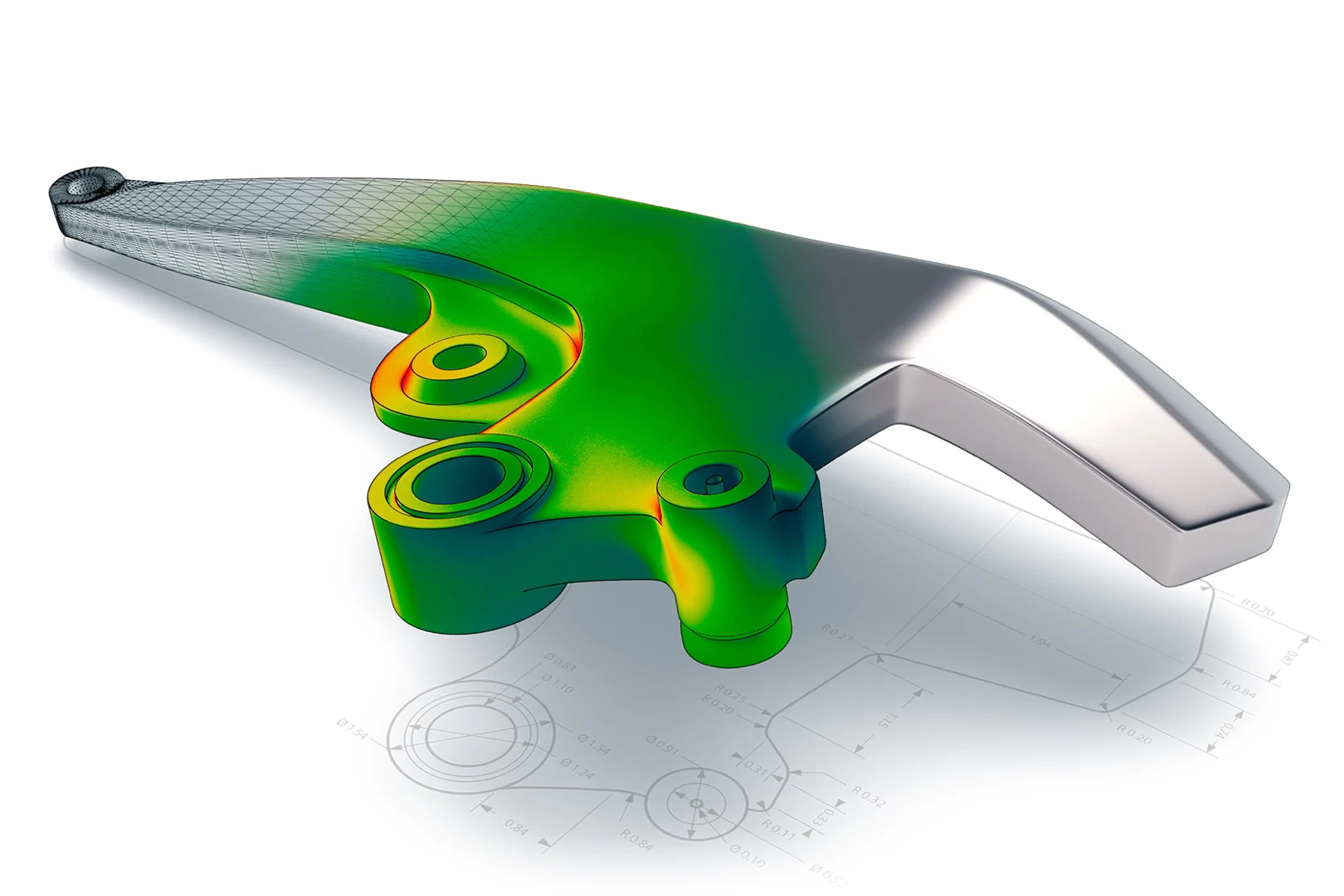

The T-SCAN is another hand-held system that delivers a highly precise 3D metrology solution for intuitive 3D data acquisition. Its modular all-in-one concept offers maximum flexibility for a large variety of applications and surfaces.

Optical tracking for small and large volumes

Combine a hand-held T-SCAN laser scanner with the optical tracking system of your choice: the established T-TRACK 20 for large measuring volumes of up to 20 m³ – or the new T-TRACK 10 for a smaller measuring volume of up to 10 m³ and higher accuracy. If you want to quickly and reliably capture individual measuring positions, choose the touch probe T-POINT. It’s the perfect solution for single-point measurements on object areas such as trimmed edges and standard geometrics or optically hard-to-reach areas.

GOM Inspect: Intuitive software for a simplified workflow

The modular T-SCAN system operates with GOM Inspect, the all-in-one, user-centered software solution and established standard in 3D metrology. Measurements and inspection can be performed on screen, the parametric function makes all process steps traceable. For a simplified, speedier and more productive workflow.

A wide range of applications

Quality Control and Inspection

- Nominal-actual CAD-to-part comparison

- Boundary edge extraction of sheet metal parts

- Inspection of complex welded structures

- Shop floor inspection

Tool and Mold making

- Tool reconstruction

- Scan data for machining path generation

- Actual capture following tool approval

- Capture of complex component dynamics, e.g. during a clamping procedure

Product development and design

- High dynamic range to scan all kinds of surfaces

- Scanning of design models for CAD downstream processing and documentation

- Gage and fixture setup

- Fast capture of reference geometries and specified areas